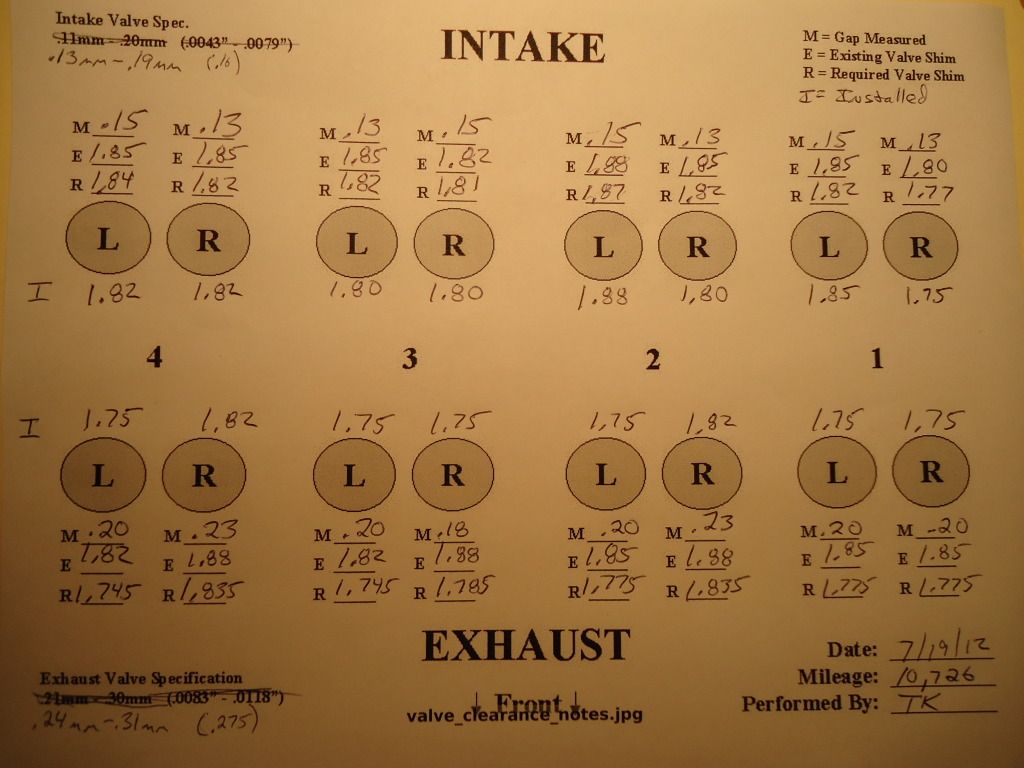

So I had the shop do the valve cover gasket on one of my '08s and I decided to do my own on the second '08 because I wanted to go ahead and check the valves and do other maintenance (new plugs, filter, etc) while I was in there. I have 10k miles on the green one now. So they gave me the gasket and I pulled it apart last night:

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

Already put new plugs in and will get check the clearance on all the valves tonight after work.

Already put new plugs in and will get check the clearance on all the valves tonight after work.